Elastomer Cutting System

View PDF

Brochure

Part 1 :

For Roller Grooving

Ver Folleto

PDF

(Español)

Main Power Supply Unit,

Power Cables, Adjustable Tool Holder, and Custom-Designed Tool Post.

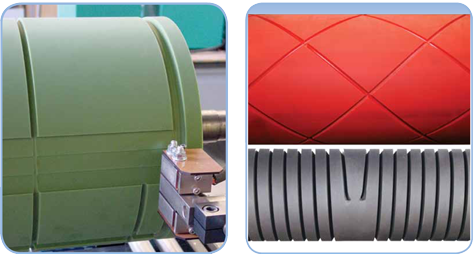

Grooves in polyurethane & rubber

Custom Tools for Special Groove Shapes Available

Various types of clean grooves can be produced efficiently

As a state-of-the-art approach to thermocutting, our system has been designed especially for the rubber roller industry to provide an advantageous method of machining elastomers in operations such as single-pass grooving, and rapid removal of excess material prior to final grinding.

A custom designed tool-post can either be permanently bolted onto the main operating machine such as lathe, or can serve as a quickly removable attachment to a grinding station(s), etc.

Flexible design of the tool holding assembly accommodates tools with a wide array of shapes and sizes, and allows for easy position adjustment for almost any cutting operation.

Our patented* blades are durable and concentrate heat specifically on the very cutting edge, thus ensuring smoke-free operation.

Thanks to this new technology your company can increase productivity, reduce clean-up time, and save on labor and energy costs. With this machine, rubber roller grooving or roughing takes minutes instead of hours! Contact Prosco Inc. for more information or a demonstration.

* US Patent #6,230,603

Also, check out:

Grooving of polyurethane roller

Grooves in polyurethane & rubber

Click on images to Play or Pause Video

Grooving Polyurethane

Spreader Groove in Soft Rubber

Elastomer Cutting System

Part 2 :

Roller Diameter Cutting Applications

View PDF

Brochure

Ver Folleto PDF

(Español)

ROUGHING

OD FINISHING

Roughing produces easy to dispose strips (Hypalon duro 75 Shore A)

Rubber OD finishing where ground finish

ROUGHING

25.4x6.4mm (1"x 0.25") strip being cut from a duro 20 Shore A printing roller at a rate of 9m(30 ft )/minute

RECYCLING

Roughing of uncured rubber allows recycling of material back to the extruder

Also, check out: